I just received this announcement in an email from one of my many electronics industry sources. It describes a new filter, used by the military to protect sensitive electronic gear from EMP or equivalent events. Just thought I’d pass it on! HEMP Filter link

Tag Archives: Ohio Solar

Adding battery backup – even if you DON’T have solar!

It’s been a while since I posted any new activities – but only because I’ve been so darned busy! A client in Harrison Indiana wanted a a solar system installed, but he launched his project too late in the year, so rather than fight the weather, we decided to just install the BACKUP portion of the project ahead of time – giving him the benefit of a backup system for the upcoming Winter season. He lives out in the country, and encounters frequent power outages during the winter months, so this was a good compromise, and that’s what this blog entry will be about.

We decided to go with the new OutBack RADIAN 8Kw inverter and the Outback AGM batteries, since they don’t require watering or venting. He had space on the wall where his current Main breaker panel was located, so we just expanded with some extra plywood. We hung the inverter and mounted the battery bank directly below it so that we would minimize the distance the 4/0 Battery cable would need to cover.

With that plan in mind, I went in search of some 1 inch plywood, which it seems none of the lumberyards carry. I got the lumberyard to precut a 4 X 8 sheet of 1/2 inch thickness, and managed to squeeze them into our PT cruiser. A couple squirts of glue and some 3/4 drywall screws to hold them together got us the mounting plate we needed for all the things we were going to add: a SUPPORTED LOAD panel – this is the loads that will be backed up when the power drops, another outlet for the freezer next to this panel, and the OutBack MATE3 control center that lets us program the Radian and observe the voltage and operation visually.

The MATE3 also provides the interface to the internet so that this can all be monitored from a PC on the web. We planned on adding solar this year when the weather warmed up, and the Radian PREWIRED INTERFACE took all the hassle out of making this all work. THe interface is directly below the Radian in the next photo. Everything inside this prewired box is clearly labeled and it would be VERY hard to get it hooked up wrong!

The next step was to move the breakers and wiring for the supported loads from the main panel (at the left) to the supported load panel (in the middle). The lines were too short by a couple of feet, so I went to the electrical supply house and found some neat nylon splice blocks that have compression screws and they come in big strips of 20 or 30, so I could cut them into blocks of 3. This allowed me to splice new romex (same gauge) to the black, white and copper ground wires in a manner that was safe and in compliance with the National Electrical Code.

The wood backing also allowed me to screw the splice blocks in place at the top of the board (out of reach) to keep things safe. Please notice that all connections between the breakerboxes, the inverter and anything else on this board are all in conduit. The only exception is the Romex, which by code is allowed. Just remember that EVERY line of romex going into the supported load panel MUST have a strain relief. You just can’t run wires through the holes in the box – it would NEVER pass an inspection!

While I was doing all that wiring, the homeowner was busily assembling the battery cabinet and installing the OutBack AGM (sealed lead acid gel type) batteries and all the jumpers to create the battery bank. There are two banks of four batteries, which are then paralleled to achieve a sizeable AmpHour capacity.

These batteries are not cheap, but they don’t require any attention like checking fluid level, or requiring a vent fan, so it simplifies the installation and use of the system. By the way, if you want a closer look, just click on the photos and you will get a full screen size view.

If you look close you’ll find that there is a 175Adc breaker for each ROW of batteries in the cabinet. This will come in handy troubleshooting in the future. It also keeps things safe while connecting the battery cables. The cable used in this setup is high strand count 4/0 with FACTORY TERMINATED ring ends. No, you CAN’T use welding cable, and don’t even THINK about putting ends on by yourself.

Always purchase SOLAR battery cables that are pre-terminated by your supplier. During normal operation DC current out of the battery can reach peaks upwards of 500 to 1000 AMPS. Any weak or loose connection will get hot and create a problem in no time!

Here’s the finished installation – just a few more lines to move from the main breaker panel over to the supported load panel. If you click on the photo, and zoom in, you can just make out those splice blocks I was talking about at the top. There was just enough room below the supported load panel to mount the Mate3, and the finished installation looks pretty nice with all the brushed steel panels and covers re-installed.

Other than the battery cabinet, the backup system didn’t take any additional floor space, so it was not a problem where we placed everything. The homeowner still needs to run an ethernet cable down a chimney chase from upstairs to put the system online – another project for a rainy day. I went back in the early Spring of this year to install the ground mount and a sunny boy inverter at the back of the property.

This is an old farm, and the service is sort of snaked around the property. By intercepting the feed to the barns, we will be able to redirect them THROUGH the RADIAN INVERTER PREWIRE BOX, and effectively create an awesome GRID BACKUP system that will operate AND Charge the batteries when the utility power is down. In Bright sun, we have 8KW from the inverter/battery bank COMBINED with 5 to 6KW of realtime solar power to run some BIG loads like AC or the washer/dryer.

If you look back at the 2nd picture, you can see TWO large boxes with cables coming from them. These are two 4Kw inverters. The RADIAN design is redundant- if one quits, you still have power, just 1/2 power. That’s better than NONE when the power is down. I think this is the best feature of the radiant design!

MOTHER EARTH NEWS FAIR 7 SPRINGS PA

Wow, thanks to all who attended my seminar this year! I changed it up a little and made it a presentation of good-to-know FACTS about solar – every aspect of it. Ended up with about 10 minutes of open questions, and I got lucky again – I was able to answer every one with a solid response! Sorry I left my NEW box of business cards at home, but I think the 12 folks who came up to get the 12 I had were the folks most interested in future contact (I hope!). I promised I’d post the PowerPoint presentation, so here it is with the presenters notes included. MEN FAIR 2014 Presentation Nothing that will rock the world, but there might be just that one photo, or factoid that you’ve been looking for! Thanks again for all who were in the PACKED tent (even if you just wanted to get out of the rain!)

A whole TOWN goes off grid in Germany!!

Found this story today, and it is really amazing how a little bit of willpower and cooperation allowed this small town in Germany to not only go OFF GRID (total disconnect!) but to also SELL power to neighboring towns at a discounted rate! Read the story here: OFF GRID GERMAN TOWN STORY

DIY Solar LOW electric bill!

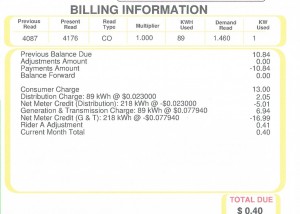

Just a quick post. I’ve mentioned my little house in the country many times and I finally found the energy hog! It was my septic aerator pump. It’s a 3/4 horse air pump, and it was running far too often. I changed the timer settings and cut my biggest energy user by 70%. I added panel #13, and I think I’ve almost reached NET ZERO energy for this little house!

Nothing makes me happier than seeing a ZERO or near ZERO electric bill. Keep in mind, the solar also covers the fixed portion of the bill that is NOT electric usage. It renews my belief that doing this is the Right thing, right now.

Solar has never been more affordable, so if you plan on staying in your home for the next 20 years, CALL ME and I’ll show you how to do DIY SOLAR in a quick, effective and above all AFFORDABLE manner! It just makes good sense.

Finish phase 2 expansion at East Fork Stables

Cinci Home Solar works with EFS to get racking up using 50% on hand materials.

Missed this photo on the first part of this adventure. The owner had materials on hand, and made the posts of Steel L channel, the beams from Steel S-channel, and the barn support brackets from 2 inch steel L material. The owner (George) is a VERY resourceful fellow – some might call him a scrounger, but I call him SMART! I passed along a great vendor deal on the solar panels and he purchased them direct. The BOS (balance of system) materials was purchased through Cinci Home Solar at great pricing, bringing the whole project in at about $3/watt, and this includes the battery bank and backup power inverters in addition to the Enphase micro-inverters behind each panel. The work was spread over 4 full days, with the helper crew varying from 1 to 3 guys and myself. Plenty of manpower to get this rather large project done in a timely fashion. Winter is really variable in Cincinnati, and whenever the weather was predicted to be above 40 and sunny, George called and we got the job done. Fortunately, this job was a quick drive from my home, and it wasn’t a problem. Normally, these 3 or 4 days would have been all condensed into one extended visit! I aim to please, whenever possible…

After we finished the 32 panel array, George saw that some minor grading of the ground near the bottom would allow plenty of room for 2 more rows! A week later he called me and said “Hey Joe, come on out and lets get these 2 rows installed – tomorrow’s weather looks great. So we did! When I ordered the extra components, we also added 8 more rails – one under each of the 8 columns of the upper 4 rows. You can see them mid-panel in the picture to the right. This provided the extra strength and rigidity that the span required for both wind and snow loading. Splicing the extra rails that extend to the newly installed lower beam also provided a counterbalance to the free span above.

The two missing panels at the lower left were intentionally left off because of a stone access road to the hay barn that George didn’t want to move.

This is what the backside looks like after everything is in place. After the rails were set, the Enphase M215 Micro-inverters were mounted. Then the #6 bare copper ground wire was run in series to each inverter. We grounded BOTH ends of the #6 copper, just because we could. Next came the Enphase TRUNK Cable, mounted with stainless steel clips to the rails. Then the panels were added, the micros were plugged in to the trunk cable and the panel leads connected to the micros. One end of the trunk cable is sealed with a weather tight cap, and the other goes to a weatherproof junction box (white) to transition to standard exterior rated 12-3 with ground romex. The romex connects to a breaker box with a 20 amp 2 pole breaker for each string of 16 and 1 string of 14 panels. Then, the entire array is nicely dressed using tie wraps so that all the wiring is suspended between the panels and the bottom of the rails to keep it from whipping in the wind or getting snagged by anything.

Power Panel beneath the array, mounted to the side of the hay barn.

Here’s the power panel. Public Utility Commission in Ohio says any array over 6Kw must be metered by a UTILITY GRADE meter. Got one on Ebay for $35. Breaker box on left contains the 3 solar breakers. That feeds through the meter to the master breaker box on the right. Master breaker box connects to the utility grid via a buried conduit over to the other barn that had power in it already. Below the utility grade meter is the Enphase ENVOY monitoring unit that ties all this to the internet so George can watch things from his home computer. He can share a link with his friends as well. I’ll post this link soon as I get it from George! The Utility voltage here is rather high – close to the limits for most inverters, at 254Vac. This causes a few of the inverters to occasionally shut down (to protect themselves). I’ll be looking into this further on my next visit to see how we might correct this…

Almost finished DIY solar array accomplished with a little help from Cinci Home Solar!

Here’s the finished array. Still need to trim the excess rail length at the bottoms. If you look close, you might just spot some mis-alignment within the array. George got 2 pallets of panels. Same part number, same vendor, but one pallet was 1/2 inch shorter on the long side (out of spec…). We didn’t catch this till 5 were mounted in the top row. George, being a prudent and thrifty fellow, called the panel supplier and negotiated a compromise that didn’t require a return of the panels. The size only affects the esthetics slightly, and a cost reduction is pending! The Enphase ENVOY normally communicates over the power lines, but there’s a half mile of them back to the house and that’s too far for it to work, so I added an Engenius EOC-1650 at the house as an access point, and atop the array as a client/bridge. It works great – with 100% signal integrity, and also provides WIFI to his customers and visitors! The EOC-1650 is that little white gadget at the top right of the array.

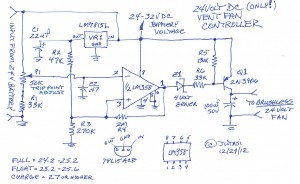

24 Volt Battery Box Vent Fan Control Circuit

Lightning Arrestors. Use them!

I’ve never discussed this, but these devices are cheap insurance (not really, but you get the idea…) against all kinds of problems that can come about as a result of electrical storms. I’ve used the powered type in the past, and have one installed currently, but I came across a totally passive version that uses no power, is self resetting, and if it does fail, it fails OPEN, so it won’t cause problems. Best of all, you can get them for 30 bucks on ebay, brand new, including shipping. Just search for “LA302R”. It has 3 wires, and you simply install it in your electric box to a breaker connected to L1, L2 and Neutral. If you’re not an electrician, hire one to do this. It takes about 2 minutes. It takes longer to get the cover off your breaker box than it does to install one!!

Serious grid-tied/grid-backup system!

Ground mounts are an attractive alternative if you don’t have much roof space and want a system that allows you to live comfortably WITHOUT the grid!!

Nestled in the middle of a 26 acre plot is this cozy updated farmhouse with almost 6KW of solar power. The home is well insulated, and fitted with all the high efficiency goodies. Propane fired DEMAND water heater, wood stove for heating, LED lighting and more! At first I assumed he wanted a ground mount to keep it away from the house, but when I arrived on site I knew right away the real reason – no room on the roof! But seriously, this setup goes way beyond just a large array. The owner wanted plenty of AUTONOMY – that’s lots of days of off grid operation without worry of running the battery bank down. And plenty of power, so that if he wants to do laundry while off grid, it won’t be a problem. So we got together and discussed the options and the owner decided to DO IT RIGHT the first time. I explained that batteries would be a large part of the project cost, and he would have to understand and CARE for the battery bank if he expected it to last 10 years or more. He was more than willing to listen, read, study and understand the care and feeding of his battery bank, and as a result is VERY pleased with his installation.

Trench backfilled, horizontal pipe (3 inch galvenized) added front and back, and vertical rails to carry the solar panels installed. Ready for panels and wiring. Owner and a few helpers accomplished this in 2 days of hard work. Not much daylight in December, but DIY folks are not afraid to work sunup to sundown!!

While all this activity was going on outside, I was busy in the basement, hanging the TWO Sunny Island inverters on the wall, mounting the small EMERGENCY POWER breaker box and running conduit between the inverters, the main breaker box and the new Emergency power box. I’d come up for air once in a while to check on the ground mount work, just to make sure it was square and plumb, but these guys knew what they were doing and got it all right on the very first pass! Looking at the pics below, we chose to use TWO Sunny Islands for several reasons. 1st and most important was that the Sunny Island is without question the best BATTERY TENDER around. It can use the grid or the array charge the batteries, and it has sophisticated software to monitor the battery health and adjust things as needed to optimize the battery care. It LEARNS over the 1st 8 weeks how the battery supplies power and how it accepts charge and then adjusts itself for the best possible care. We used TWO Sunny Island inverters so that we could SLAVE them together and create 240VAC “split” phase. The Sunny Island is a 120VAC unit and would otherwise need a lossy transformer to boost the output to 240VAC. We doubled the available continuous output power to 13,000 WATTS by doing this. That is a LOT of backup power, and will allow completely normal living in an off grid situation. The owner wanted lots of autonomy (days of power off grid) so we went with the largest batteries withing the budget – Rolls FLA 6 volt 820AH. EIGHT of them to reach the 48VDC the Sunny Islands need. That’s almost 40KWH of backup power. And remember, when off grid, the sun on the array will recharge them, as well as power the house! I didn’t have time to hang around while a battery BOX was built, so we put up a poly tent and connected the vent fan. This was only a temporary fix and has since been replaced by an appropriate battery box. The exhaust fan is programmed to come on while the batteries are charging – since this is when they give off Hydrogen gasses which are explosive in small amounts. The owner has since also installed RECOMBINATION CAPS which reduce the outgassing by 99% and reduce fluid losses considerably – making it only necessary to check acid levels in the battery every two months or so, rather than every 2 weeks. A wise investment – since it minimizes outgassing of Hydrogen if the vent fan were to ever fail! Batteries are a VERY serious bit of hardware and you MUST care for them if you expect to get 10+ years of service! Always wear safety glasses, a rubber apron and rubber gloves when checking/filling the cells!

Some of the AC lines have been moved to the emergency breaker box, all covers are on, and temporary poly cover over battery box has been connected to the power vent fan. When the battery bank charges (at 38 amps DC) the batteries bubble up hydrogen gas and without the fan and cover, the room would reach explosive hydrogen levels in less than 1 minute. NEVER power up a battery system without a vent system!! A 4% concentration level of Hydrogen gas is highly explosive.

Two Sunny Island battery/inverters on the wall, eight 6 volt 820AH batteries below elevated off floor to make watering easier. DC cables connected and AC interconnections in Plastic conduit for safety. Ready to move some wiring from the main box to the emergency breaker box. Only items in the emergency box will be powered when running off grid. System cuts over instantly when grid drops out. Barely a flicker of the lights, it happens so fast! Same thing happens when power is restored. Back on grid in an instant.

When a lead-acid battery is discharged, the electrolyte (sulfuric acid) and the active material on the plates of the battery (lead) are consumed to produce water and lead sulfate and current flow. The chemical equation for a lead-acid battery during discharge is: PbO2 Pb 2H2SO4 –>PbSO4 2H2O Ideally it’s just hydrogen gas, but when doing Equalization charging, you’re going to get some hydrogen sulfide as well – you’ll know it by it’s Sulfur smell and the stinging sensation to your eyes! Make sure the battery box power exhaust fan works BEFORE you turn on your system. In this setup, I programmed the fan to run whenever the batteries are charging. As long as the fan is running, there is negative pressure in the box (or temporary tent in this case) so even any holes or leaks will take fresh air IN to the box/tent and then OUTside the house through the white PVC vent at the left. Happy to say that the 1st charge cycle was free from problems and there wasn’t even the tiniest hint of any gas in the room. The use of RECOMBINATION caps is HIGHLY recommended. They will eliminate almost all of the outgassing and make the battery liquid levels go down MUCH slower.

Backup System finished at Little House

Wow, it’s taken a while to get this posted, but I’ve got the grid-backup system completed at our little house (we fondly refer to it as THE BUNKER…). I was recently out there during a freak snow storm that dumped 5 inches of wet snow in about 2 hours, and when the power went out, there was just a slight flicker of the lighting as I was sitting at the computer checking my email. The UPS on the computer didn’t even get a chance to kick in! I excitedly went downstairs to the basement to check out the inverter, and sure enough, it was on line, quietly humming away, providing full power to the main electric breaker box for everything that was presently on in the house. The Magnum MS-PAE 4024 inverter can provide about 4,000 watts of continuous power until the batteries discharge 80% of their capacity. Since the house normally consumes only about 500 watts (average) power, this represents about 20 hours of run time. Fortunately, when the backup system is in operation, the solar PV system can “back feed” through the breaker box and provide the power the house needs as well as re-charge the batteries, so this setup can run pretty much indefinitely, as long as there is a few hours of sun each day. Even on a cloudy day, the 2.4KW (Twelve 220 watt panels) solar array provides about 500 watts, so that extends the capacity of the system pretty well.

In order to make the TRANSFER SWITCH operate, I had to build my own little GENSET SIMULATOR. It connects to the output of the backup inverter and provides the necessary voltage and control signal to the transfer switch to make it kick over when the power goes out. These TRANFER SWITCHES are designed to normally work with a gas or diesel GENERATOR SET, as they are called.

It took a little studying and research, but I figured out how to SIMULATE the voltage and signals that normally come from a GENERATOR SET that would connect to a WHOLE HOUSE TRANSFER SWTICH on the V+, GROUND, and PIN 23. These are the 3 wires that are standard on any gas or diesel generator. Since I’m using an electronic inverter (Magnum MS-PAE 4024), such signals were not available, so I came up with a little box that has 2 relays in it. One is standard and the other is a 5 second delay unit so the system won’t “chatter” if power drops in/out rapidly. If you’d like the details on how to build one, I’ll be glad to send you a schematic. Just drop me a line at: Joe@cincihomesolar.com

These are the batteries I chose. Since I’m on a tight budget, I chose the best bang-for-the-buck, and it ended up being the Rolls 6 volt 520AH model. I splurged on the funky looking RECOMBINATION CAPS, rather than the normal vented caps that come with the batteries. By installing the RECOMBINATION CAPS, the hydrogen gas generated during charging is sealed inside the battery 99%, and the battery loses MUCH LESS liquid over time than a VENTED battery would. A box and vent fan are still required for safety though, and I will add this to complete the project very soon. Without these special caps, in just 30 seconds of charging at 90 amps, the hydrogen gas coming from the batteries would reach 4% concentration and become highly explosive, so this is nothing to fool around with! VENT YOUR BATTERY BANK TO THE OUTDOORS!